Hastelloy C276 Wires Manufacturer, Supplier and Exporter in India

Labdhi Metals is a trusted manufacturer, stockist, and exporter of Hastelloy C276 Wire, known for delivering high-performance corrosion-resistant alloys that meet the needs of the most demanding industries. Hastelloy C276 Wire is a nickel-molybdenum-chromium alloy with an addition of tungsten and low carbon, offering superior resistance to a broad range of aggressive chemicals, including strong oxidizers and reducing agents. The wire is extensively used in chemical processing, marine environments, pollution control, pulp and paper, and power generation industries.

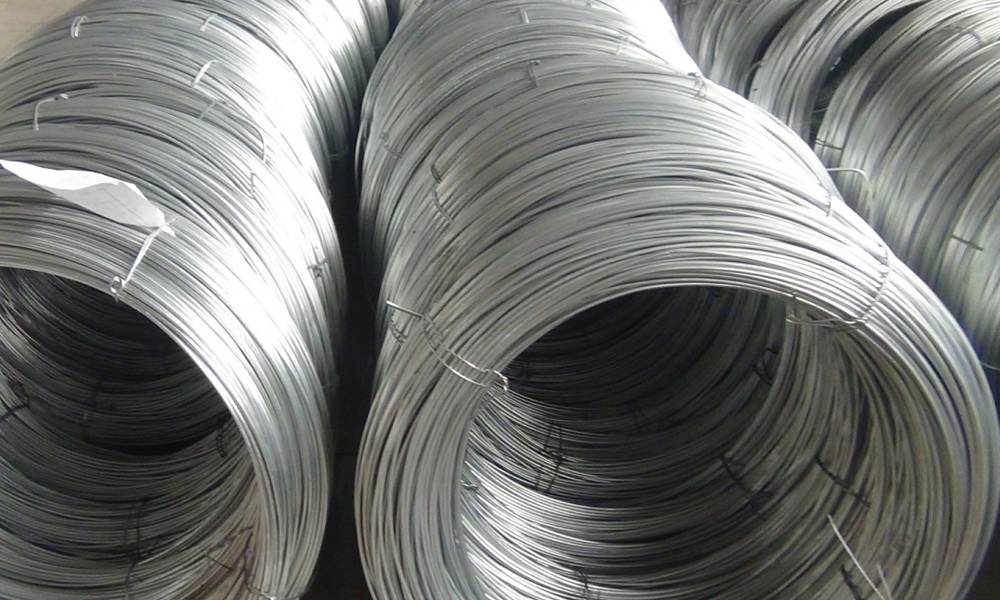

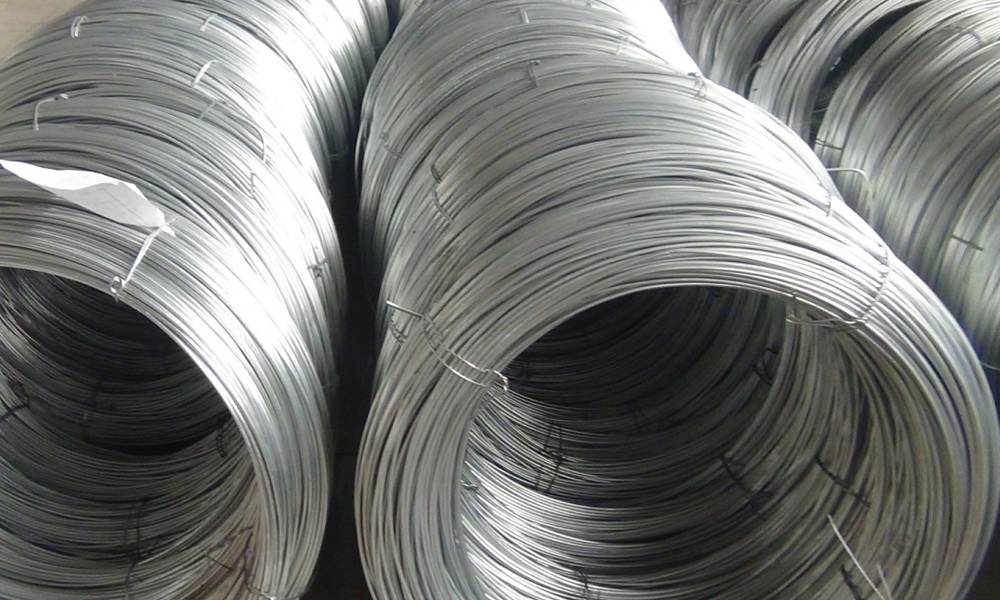

As a professional manufacturer, Labdhi Metals produces Hastelloy C276 Wire to international standards like ASTM B574. The wire is available in various tempers—soft, hard, spring—as well as in different finishes such as bright, clean, and oxidized. The production process involves high-precision drawing, annealing, and surface treatment to ensure excellent ductility, surface quality, and dimensional accuracy. It is suitable for welding applications, resistance heating, mesh weaving, and component fabrication in corrosive environments.

As a reliable stockist, Labdhi Metals maintains a large inventory of Hastelloy C276 Wire in sizes ranging from 0.1 mm to 6 mm in diameter, catering to both bulk and urgent requirements. The wire is supplied in coil, spool, or cut-length form, based on customer needs. With ready-to-dispatch stock and competitive pricing, Labdhi Metals ensures consistent supply to a variety of industrial sectors and OEMs.

In its role as a global exporter, Labdhi Metals supplies Hastelloy C276 Wire to clients in the USA, Germany, UAE, Saudi Arabia, South Africa, and other countries. Products are securely packaged to avoid damage during transit and include full documentation, such as third-party inspection certificates, mill test reports, and compliance with ASTM and ASME standards. Their efficient logistics and customer service have made them a preferred supplier in international markets.

| Property | Details |

|---|---|

| Product Name | Hastelloy C276 Wire |

| Standards | ASTM B574 / ASME SB574 |

| Diameter Range | 0.1 mm to 6 mm |

| Forms | Coil, Spool, Cut-Length |

| Tempers | Annealed (Soft), Spring Hard, Full Hard |

| Surface Finish | Bright, Oxidized, Cleaned |

| Applications | Welding, Springs, Mesh, Seals, Heating Elements |

Hastelloy C276 Wire is particularly valued for its ability to withstand localized corrosion, including pitting and crevice corrosion, in both oxidizing and reducing conditions. It performs reliably in environments containing wet chlorine gas, hypochlorite, and chlorine dioxide. Labdhi Metals continues to be a leader in supplying corrosion-resistant alloy wires, offering quality, technical support, and prompt delivery across the globe.

| Element | Composition (%) |

|---|---|

| Nickel (Ni) | Balance |

| Molybdenum (Mo) | 15.0 – 17.0 |

| Chromium (Cr) | 14.5 – 16.5 |

| Iron (Fe) | 4.0 – 7.0 |

| Tungsten (W) | 3.0 – 4.5 |

| Cobalt (Co) | ≤ 2.5 |

| Manganese (Mn) | ≤ 1.0 |

| Vanadium (V) | ≤ 0.35 |

| Silicon (Si) | ≤ 0.08 |

| Carbon (C) | ≤ 0.01 |

| Sulfur (S) | ≤ 0.03 |

| Property | Value |

|---|---|

| Tensile Strength (MPa) | ≥ 760 |

| Yield Strength (MPa) | ≥ 283 |

| Elongation (%) | ≥ 40 |

| Hardness (Rockwell B) | ≤ 100 |

| Density (g/cm³) | 8.89 |

| Melting Point (°C) | 1325 – 1370 |

Mumbai, Ghaziabad, Vijayawada, Vadodara, Faridabad, Madurai, Jaipur, Coimbatore, Trivandrum, Mysore, Agra, Vapi, Aurangabad, Gurugram, Aligarh, Jamnagar, Thiruvananthapuram, Meerut, Bhubaneswar, Kolkata, Bhopal, Lucknow, Rourkela, Ranchi, Thrissur, Patna, Chennai, Indore, Jodhpur, Bangalore, Allahabad, Visakhapatnam, New Delhi, Surat, Kanpur, Rajkot, Nagpur, Jamshedpur, Bhavnagar, Chandigarh, Nashik, Ahmedabad, Noida, Bareilly, Kochi, Bharuch, Hyderabad

United Kingdom, Turkey, Angola, Oman, Bahrain, Denmark, Indonesia, Canada, Egypt, Argentina, Saudi Arabia, Kazakhstan, Singapore, Thailand, Poland, Ukraine, Italy, Congo, Sri Lanka, Venezuela, South Africa, China, Qatar, Mexico, Kenya, Germany, Bangladesh, Algeria, Peru, Kuwait, USA, Russia, Australia, Vietnam, Brazil, Netherlands, Japan, Philippines, France, UAE