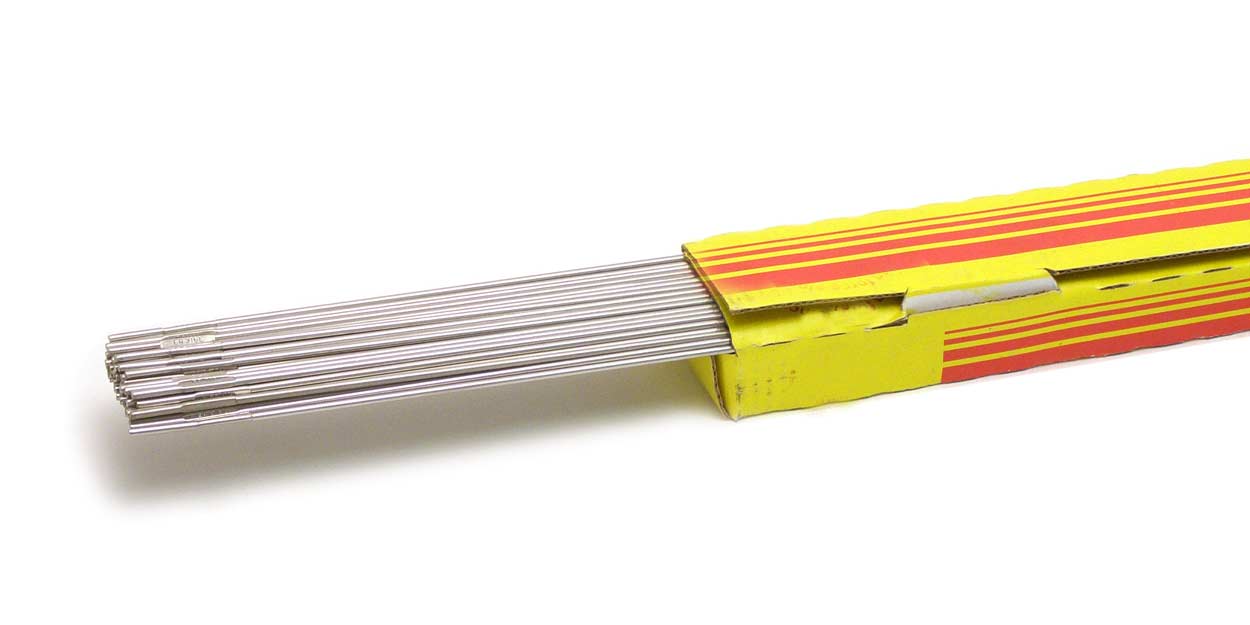

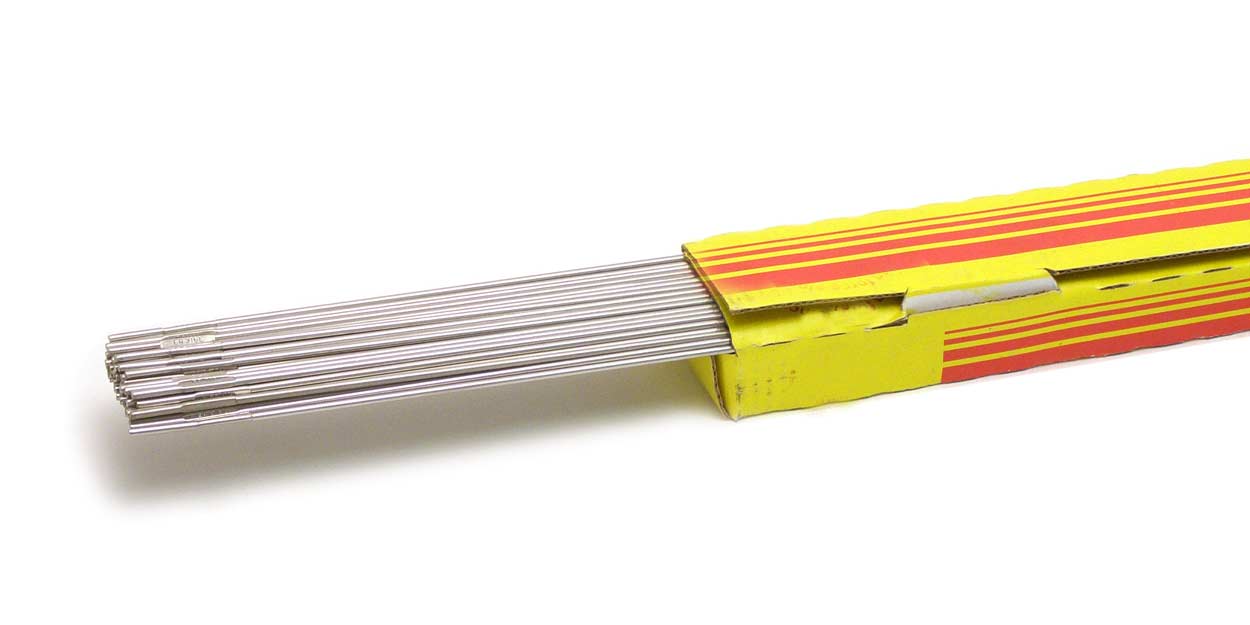

Inconel 625 Welding Rods Manufacturer, Supplier and Exporter in India

Inconel 625 Welding Rod is a high-performance filler metal made from a nickel-chromium-molybdenum-niobium alloy that is widely recognized for its superior resistance to corrosion, oxidation, and high-temperature environments. This welding rod is used in critical applications such as marine structures, offshore oil rigs, aerospace components, and chemical processing equipment. Labdhi Metals, a leading manufacturer, stockist, and exporter, offers Inconel 625 Welding Rods in various diameters and packaging formats to meet global industrial demands.

Designed for Gas Tungsten Arc Welding (GTAW/TIG) and Shielded Metal Arc Welding (SMAW), Inconel 625 Welding Rod delivers excellent weldability, strength, and crack resistance in both structural and overlay applications. The high molybdenum and niobium content enhances the weld metal’s resistance to pitting and stress corrosion cracking, especially in harsh chloride-containing environments. Labdhi Metals supplies these rods with precise chemical control and ensures consistent performance in demanding welding operations.

Each rod is manufactured with stringent process controls and is tested for dimensional accuracy, weld fluidity, deposition rate, and mechanical integrity. Whether used for joining Inconel alloys or as a buffer layer in dissimilar metal welding, the Inconel 625 Welding Rod from Labdhi Metals is trusted for its excellent metallurgical and corrosion-resistant properties. These rods also retain strength at elevated temperatures, making them ideal for heat-exposed parts like exhaust systems, gas turbines, and furnace components.

Labdhi Metals stocks and exports Inconel 625 Welding Rods that conform to international welding standards including AWS A5.14 ERNiCrMo-3. The company provides rods in lengths typically ranging from 300 mm to 1000 mm, in diameters from 1.6 mm to 6.0 mm, and offers packaging in vacuum-sealed or moisture-proof containers. The rods are certified with Mill Test Certificates (MTC), and third-party inspection (TPI) is available upon request.

| Standard | Details |

|---|---|

| AWS Specification | AWS A5.14 / ERNiCrMo-3 |

| UNS Number | UNS N06625 |

| Diameter Range | 1.6 mm – 6.0 mm |

| Length | 300 mm – 1000 mm |

| Welding Processes | TIG (GTAW), SMAW, MIG (optional filler use) |

| Packaging | Vacuum-packed, moisture-resistant boxes |

With a growing global footprint, Labdhi Metals exports Inconel 625 Welding Rod to major industrial markets including the USA, Germany, UAE, Saudi Arabia, South Africa, and Southeast Asia. Known for quality assurance, technical support, and timely delivery, Labdhi Metals is a trusted partner for welding consumables in high-performance environments.

| Element | Content (%) |

|---|---|

| Nickel (Ni) | ≥ 58.0 |

| Chromium (Cr) | 20.0 – 23.0 |

| Molybdenum (Mo) | 8.0 – 10.0 |

| Niobium (Nb) + Tantalum (Ta) | 3.15 – 4.15 |

| Iron (Fe) | ≤ 5.0 |

| Cobalt (Co) | ≤ 1.0 |

| Carbon (C) | ≤ 0.10 |

| Manganese (Mn) | ≤ 0.50 |

| Silicon (Si) | ≤ 0.50 |

| Phosphorus (P) | ≤ 0.015 |

| Sulfur (S) | ≤ 0.015 |

| Property | Value |

|---|---|

| Tensile Strength | ≥ 827 MPa |

| Yield Strength | ≥ 414 MPa |

| Elongation | ≥ 30% |

| Hardness | Rockwell B94 – C30 |

| Melting Range | 1290–1350 °C |

| Density | 8.44 g/cm³ |

Mumbai, Ghaziabad, Vijayawada, Vadodara, Faridabad, Madurai, Jaipur, Coimbatore, Trivandrum, Mysore, Agra, Vapi, Aurangabad, Gurugram, Aligarh, Jamnagar, Thiruvananthapuram, Meerut, Bhubaneswar, Kolkata, Bhopal, Lucknow, Rourkela, Ranchi, Thrissur, Patna, Chennai, Indore, Jodhpur, Bangalore, Allahabad, Visakhapatnam, New Delhi, Surat, Kanpur, Rajkot, Nagpur, Jamshedpur, Bhavnagar, Chandigarh, Nashik, Ahmedabad, Noida, Bareilly, Kochi, Bharuch, Hyderabad

United Kingdom, Turkey, Angola, Oman, Bahrain, Denmark, Indonesia, Canada, Egypt, Argentina, Saudi Arabia, Kazakhstan, Singapore, Thailand, Poland, Ukraine, Italy, Congo, Sri Lanka, Venezuela, South Africa, China, Qatar, Mexico, Kenya, Germany, Bangladesh, Algeria, Peru, Kuwait, USA, Russia, Australia, Vietnam, Brazil, Netherlands, Japan, Philippines, France, UAE